BMG’s Regional Service Centres (RSC) which are situated in the major centre cities and commercial nodes throughout the country, play a critical role by providing engineering solutions – including hydraulics, lubrication, greasing and pneumatics services – designed to optimise productivity for every customer.

“Through the consolidation of BMG’s regional workshop facilities and field services into centralised hubs, dedicated RSC’s are able to assist customers who are faced with a lack of engineering expertise, costly machinery repairs and unnecessary downtime periods,” explains Daniel Feiteira, BMG’s Business Unit Manager – Fluid Technology High Pressure division. “Our specialist service centres, with assembly, repair, maintenance and support operations, offer combined technical expertise and value–added product solutions. These dedicated service centres, which focus on core BMG divisions – including hydraulic, lubrication and pneumatics, drives, gaskets and materials handling – operate closely with dedicated branches, to meet every customer’s specific requirements.

“Advantages for customers include improved service, repair and delivery efficiencies, centralised technical support and easy accessibility to BMG’s comprehensive range of quality branded engineering components.

“An important focus of RSC’s is on fluid technology services that integrate quality branded components, full turnkey engineering and contamination control, as well as a test and repair services, to ensure optimum performance and extended service life of all Fluid Technology hydraulic and lubrication systems.

“BMG is able to assist with design, manufacture and assembly of all hydraulic, lubrication and pneumatic systems, whether it is for a workshop, process upgrade or of a hydraulic system for an entire new plant.

“Our highly-experienced teams work in consultation with customers to ensure the most efficient solution – from small multi-purpose power packs to large power packs for mining and industrial applications. Key industries in the region include sugar, agriculture, shipping, mining, automotive, power and petrochemical plants, manufacturing and general engineering.”

BMG follows stringent ISO accredited procedures to ensure the integrity of every hydraulic system. Each repaired component is assessed by the company’s testing facility and certificates are issued as assurance that equipment has passed the strictest performance standards.

These products include variable and fixed displacement pumps, industrial and mobile valves, low and high-speed motors, as well as cylinders and accumulators.

A critical element in any hydraulic system is contamination control. BMG’s systemic approach to fluid analysis emphasises the benefits of a system that is maintained through the use of high-quality filtration equipment, coupled with a regular sampling and testing programme. An efficient fluid analysis service ensures improved performance, extended life of components and reduced maintenance costs.

The company’s service to the hydraulics sector also includes a mobile workshop that is fitted with tools, equipment and quality branded spares, to be able to efficiently perform functions like troubleshooting, on-site repairs, installations, commissioning and system flushing. This service also incorporates on-site fluid analysis and hose and pipe assembly.

A recent success for BMG was the design and manufacture of a radial door Hydraulic Power Unit (HPU) urgently required to operate an ore pass radial door at a process operation in Zambia.

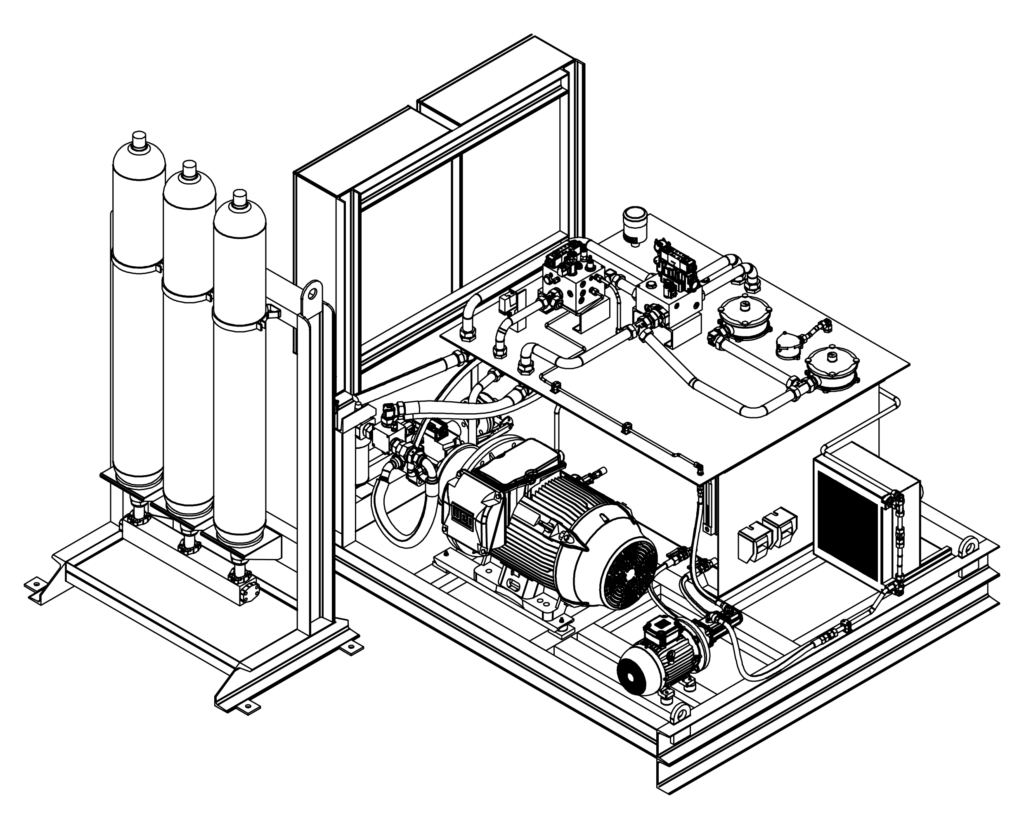

This large-scale project required a system that would open and close one cylinder with a stroke of just under 1,5m via 15m hoses, ensuring high performance, precision and control. BMG’s solution, which included 56 unique components listed on the general assembly drawing, was an HPU system mounted on a large 630 litre tank and supporting frame, with two 525V high-efficiency motor pump sets, three 55 litre accumulators and two electrical control panels.

The system utilises various push buttons and switches to control key features – including oil level, temperature, pressure, power failure or emergency, as well as directional control. The smart design of the system makes use of one 55 kW motor pump set to operate the cylinder, while the 4 kW motor pump set charges the accumulators and cycles oil through an auxiliary cooler.

In the event of an emergency, the operator can press the emergency stop button to switch off all pumps and lock the cylinder in place or push the emergency close button that will switch off all pumps and close the gate with the pressurised fluid stored in the accumulators. The latter action will also automatically take place in the event of a power failure.

The completed HPU and cylinder system, which was successfully installed in Zambia at the beginning of 2022, ensures that mined ore is passed efficiently through the material movement channels by regulating the radial gate control.

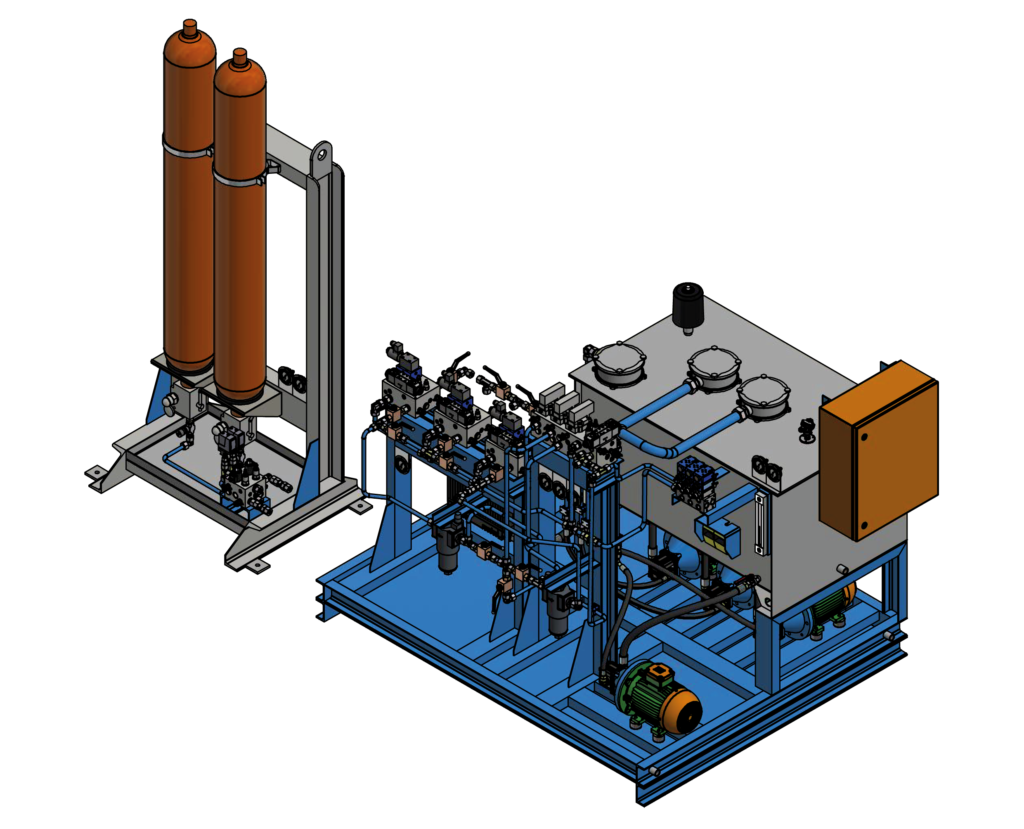

The BMG Hydraulics engineering team has recently designed an HPU that will be used on a newly built furnace in Poland. With 10 pages of specifications and requirements presented by the customer, the challenging design process needed the BMG team to closely consider the unique hydraulic system design, components and system operational parameters.

The design of this system commenced with consideration between one power pack for each of the two furnaces requiring an HPU, or a shared system that could supply the necessary operation to both furnaces, which are situated 15 m apart.

The duty of this hydraulic system, which forms part of a 2 MW DC furnace, is to control hydraulic cylinders that raise and lower a baked graphite electrode. Two cylinders work together to slip the electrode – which begins with an arm being lowered and a new electrode being added with the use of a crane, followed by the clamping cylinder being pressurised and the lifting cylinder raising the electrode with the arm. Once the electrode is in place, the lifting cylinder will lower under the mass of the arm and mast, while the electrode is consumed in the furnace. The control of the hydraulic system can be accomplished by a PLC, or an operator in the control room or on the platform above the furnace.

This HPU, which was designed by BMG for this prestigious project, conforms with stringent CE certification for operation in Europe. CE certification and conformity were carried out in conjunction with a third-party assessor, in order to precise meet customer requirements. All relevant information was consolidated into a data pack by the Engineering department.

This HPU efficiently combines a number of motors, pumps, accumulators, directional valves, pressure relief, flow control and filtration components. This system demonstrates how common hydraulic components can be applied to smartly achieve fine control and regulated operation of two cylinders in an exceptional application, such as the electrodes used in these furnaces.

BMG has made substantial investments in manufacturing capabilities in order to efficiently service the hydraulic industry for manifold blocks and cylinder manufacture. There are dedicated hydraulic cylinder servicing workbenches for the repair, servicing and rebuilding of cylinders, as well as a capability of testing equipment up to 700 bar, in conjunction with the Enerpac brand.

In accordance with stringent quality and safety specifications, BMG adheres to a strict protocol for all cylinder repairs by keeping an accurate record of all work done. When a cylinder comes into BMG for repair, it is stripped, washed and all components are tagged and hard-stamped for traceability. After components have been refurbished, they are inspected before the unit goes to final assembly. All cylinders are tested and painted before delivery.

BMG enhances its manufacture and repair service with a total design solution, using the latest CAD and CAM software. This service encompasses expertise from manifold design, to manufacturing and assembly of a complete system. The company’s 3-D modelling programmes clearly exhibit the interior and exterior of a manifold in a virtual environment – this enables the identification and amendment of possible design flaws before fabrication commences.

BMG provides a 24-hour customer process support for production efficiency and reliability centred maintenance throughout southern Africa. This service is enhanced by advanced technical and design support across all functional disciplines.

BMG’s comprehensive range of equipment and components includes bearings, seals and gaskets; power transmission; hydraulics and pneumatics; fluid technology and filtration; drives, motors and controllers; materials handling; fasteners and tools.

BMG’s Regional Service Centres (RSC) which are situated in the major centre cities and commercial nodes throughout the country, play a critical role by providing engineering solutions – including hydraulics, lubrication, greasing and pneumatics services – designed to optimise productivity for every customer.