Fifteen years ago, Lubrication Engineers (LE) South Africa began supplying its Pyroshield 9000 Synthetic Open Gear Lubricant to a major freight rail company in South Africa. Since then, the customer has tested 38 other products to compare their performance on its locomotives, but none of them has been able to deliver the same level of traction lubrication.

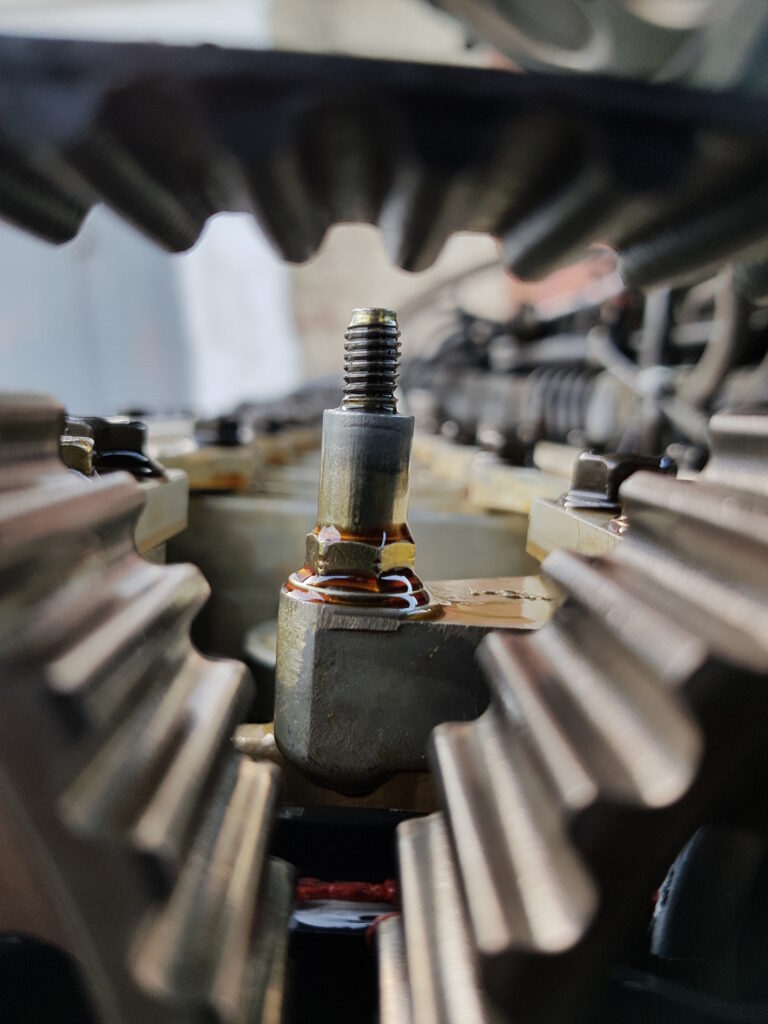

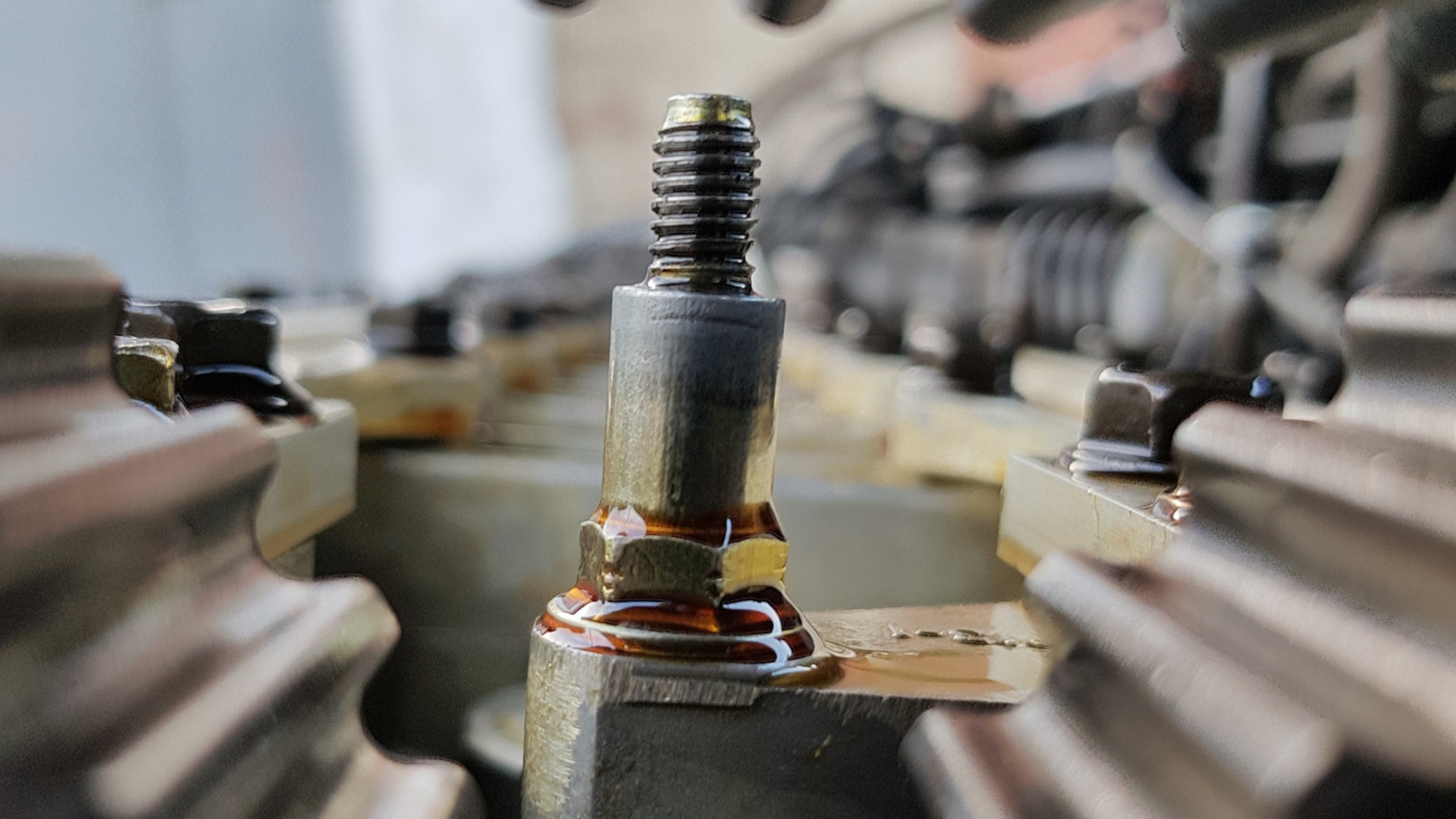

When LE began working with this company, the lubrication product the customer was using at the time was more of a compound than a lubricant and created a “sponge” between the gears. However, over time this sponge caused wear and cracking in the gears. It was also particularly problematic in extreme temperatures and when the trains were in the Karoo during the winter months, gearboxes would stick because the lubricant had frozen.

In contrast, the LE Pyroshield product, which contains LE’s proprietary Almasol additive, is a thin film product that has a high protection value and which is able to perform well at both very cold and very hot temperatures – and everything in between.

LE South Africa MD Colin Ford explains that Almasol is a solid wear-reducing additive, able to withstand extremely heavy loads, chemical attack and extremely high temperatures. It minimises metal-to-metal contact and the resulting friction, heat and wear. This protects the gearboxes and increases their lifespan. The lubricant is also a “working conversion” product, which means there’s no downtime – the lubricant can be added to the system without removing any old product in the traction motor gearbox and will break down any other product already in the system.

Before switching over to Pyroshield 9000, the client ran trials against the compound that it was already using. It took profiles of the gear teeth to see how much wear there was compared to the original product that it used. The reports show that Pysroshield dropped the wear by 98% during the trial period, which meant that there was 2% wear, as opposed to 100% wear, in the same trial period with the original lubricant.

“Since they began using this product, many of the gears haven’t needed to be replaced in years because the lubricant is doing such a good job,” says Ford. “We supply thousands of kilograms of product per year of our Pyroshield 9000 Synthetic Open Gear Lubricant to this customer, and it’s wonderful to know that it is performing so well for them.”

Tailoring supply quantities

LE initially supplied the Pyroshield product in standard 20-litre quantities, but following a request from the client for smaller units, LE worked with a local contractor to package it into smaller 500g sachets.

This repackaging into sachets has helped the customer to gauge and mete out the correct lubrication quantities for the different locomotives in its fleet. It also allows for more precise stock management and is a great example of positive collaboration between a lubrication supplier and customer.

“We are also able to supply the customer with a detailed annual report on how much lubricant they have used on a month-to-month basis, what quantities its different depots and locomotives around the country have used and what their cost per locomotive has been,” says Ford.