Recreational fishermen and ski boat owners often make significant investments when buying their equipment. But what happens when it comes to maintaining that equipment? In the worst-case scenario, if the right lubrication for the conditions isn’t used, machinery can fail, which at sea can result in serious and even life-threatening consequences.

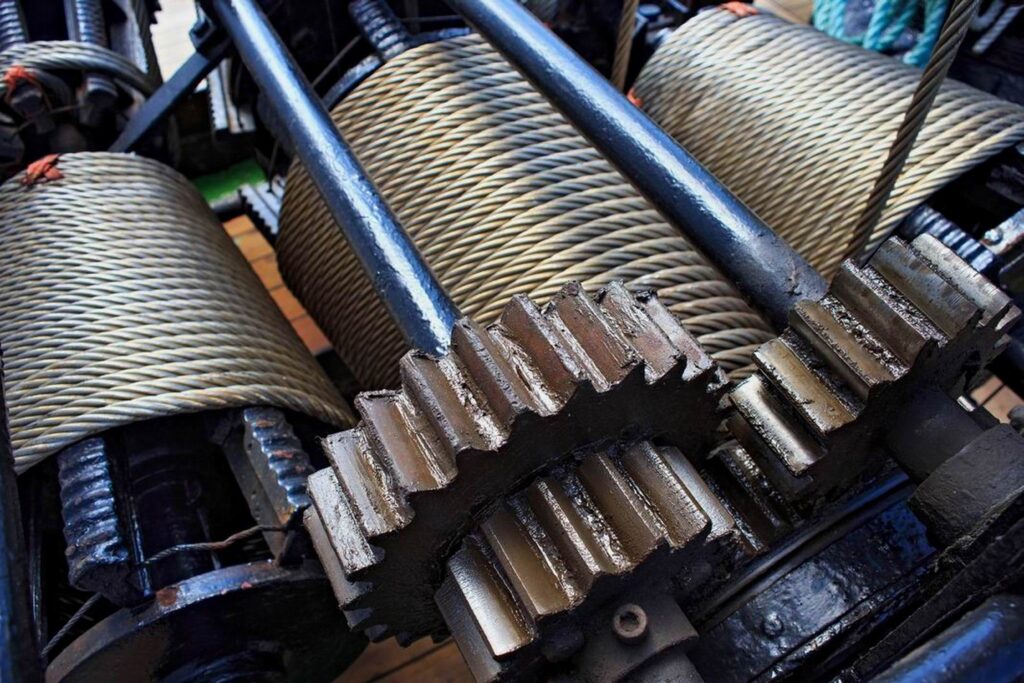

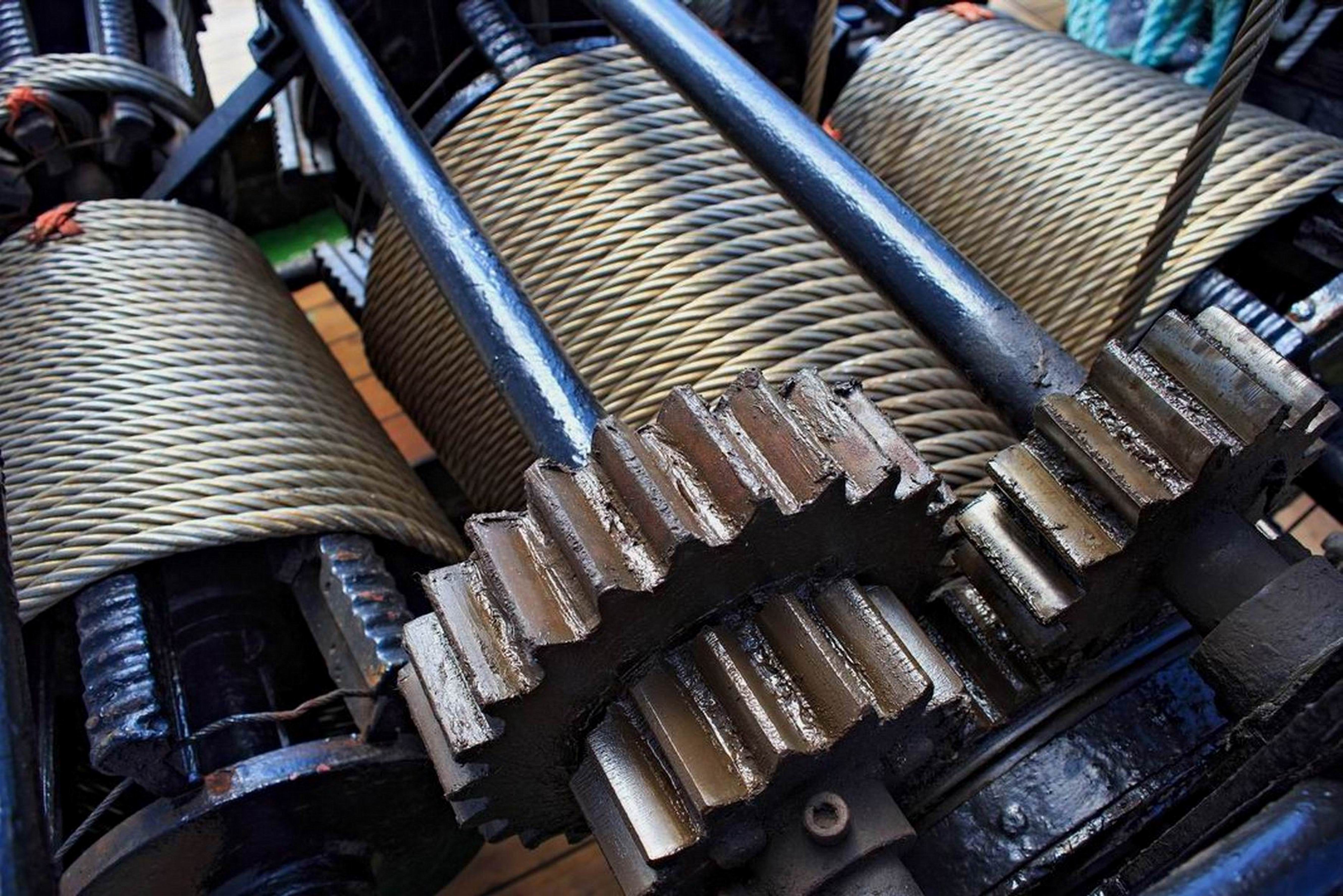

One of the biggest problems with seaborne vessels is that corrosion leads to exponential damage that often causes dramatic breakdowns. In ski boats, components like the beaching kit become susceptible to water over time, and once any water enters, it can cause the failure of gearbox oils or further damage – which could be anything from a broken shaft to an entire gearbox being snapped off.

So how can recreational sea-sport lovers take care of their assets? Lubrication Engineers (LE) South Africa’s National Sales Manager Llewellyn Owen says that it can be challenging for people because it’s about more than walking into a hardware store or parts store and taking the first option. “People think oil is just oil, and that’s not the case,” he adds.

LE South Africa has been a sponsor of the Shelly Beach Ski-Boat Festival since 2018 and part of why the company became involved with the Shelly Beach Ski-Boat Club was to be able to more actively help the club’s members understand what types of lubrication work best for their vessels. “If you’re spending money on something, you need to make sure that you’re looking after it properly with regard to what products can be used and how they can further protect your assets,” says Owen.

On ski boats and trailers, there are a number of different elements, all of which need the correct lubrication to protect them, whether it be wheel bearings, gearboxes, engines, protection engines, corrosion prevention or electronics that are held within the within these units.

Long-term protection

Three of the products that LE has which work well for coastal applications are its Duolec Gear lubricant, its Monocal bearing grease, and the CorrosionX product that LE supplies in South Africa. “For our clients at the coast, CorrosionX has been very, very effective in the protection of the inside of the cowlings on motors and for electronics inside ski boats,” says Owen.

CorrosionX uses a technology that causes it to stick to metal almost like a magnet. This ‘polar bonding’ technology means CorrosionX is attracted to metal, and physically displaces any moisture and electrolytes that accelerate the corrosion process, including saltwater. CorrosionX then leaves an ultra-thin, self-healing film that actively seals metal from the environment and stops corrosion. CorrosionX is also electronics safe – it won’t short sensitive circuits or interfere with electrical connections.

The Monocal grease is excellent at protecting gearbox bearings because it is able to resist salt, which is a significant benefit in marine applications. “I’ve got two or three trailers from the ski club that have now been running on Monocal grease for four years; where historically they were replacing bearings every year,” says Owen. The Duolec Industrial Gear Oil product is also producing reliable long-term results for clients who use it on their gearboxes.

LE has worked with a wide range of clients at the coast, from harbour-related activities to launch sites and, as Owen explains, people have been “blown away” by the results they see when using the right lubrication product for their needs. “The more time and effort that you put into buying the correct lubricant. The longer you can protect your asset and the safer you can be at sea,” he adds.