Included in BMG’s extensive portfolio of industrial slurry valves is a range of pinch valves, which have been developed to control the flow of liquids, powders, solids and abrasives in many industries.

“BMG’s Fluid Technology division’s strategy to meet constantly changing market demand encompasses the introduction of new products, with the latest developments in design technologies, materials and coatings,” explains Willie Lamprecht, Sales Manager, Fluid Technology division, BMG. “Pinch valves have been added to our product offering, enhancing our wide range of industrial slurry valves, that also includes butterfly, gate, diaphragm, ball and check valves.

“The Fluid Technology team boosts specialist services with dependable technical support to customers in all sectors, to ensure optimum safety, efficiency and extended service life of every system. Failure of a valve and subsequent leaking of corrosive media can have devastating effects on the safety of personnel and equipment, leading to premature system failure and costly downtime. With broad technical capabilities, our specialists advise on correct valve selection and installation for every application and are able to solve problems, even in corrosive environments, where conventional components have failed after short periods of service.”

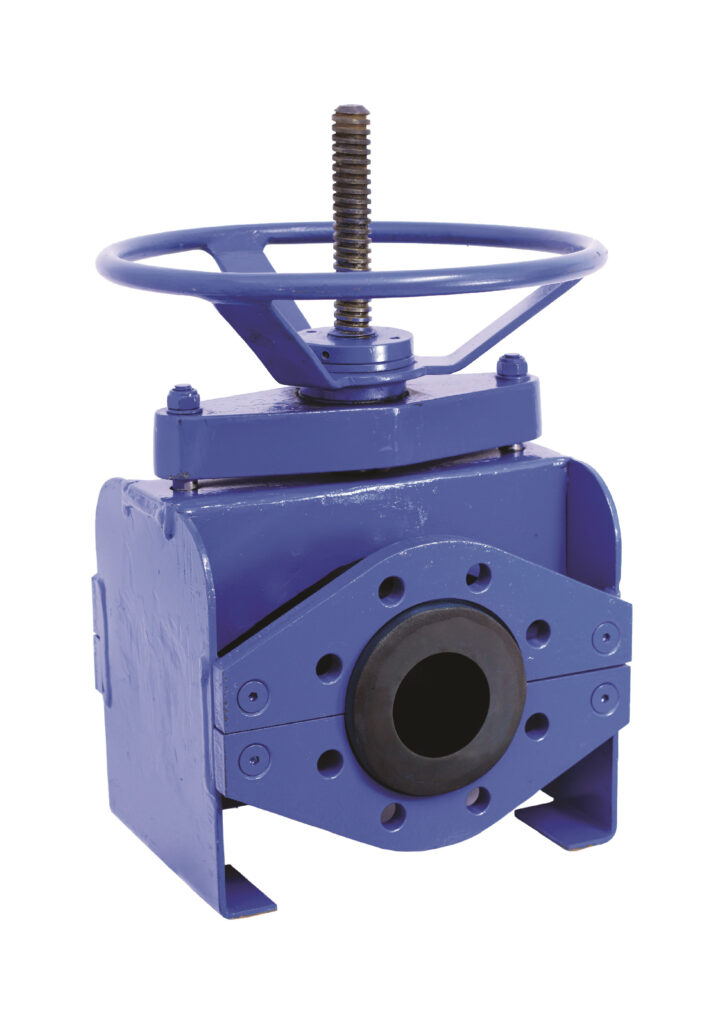

BMG’s range of pinch valves – which meets stringent quality and safety specifications – is available with nominal bore sizes from DN50 up to DN500, in either short or long open frames, with safe working pressures up to 25 bar. These valves can be tailored to suit specification application requirements, with Stainless Steel frames if required. Standard pinch valves can withstand operating temperatures between -20ºC and +80ºC and higher temperatures on request. These valves have manual, gearbox, pneumatic and hydraulic actuation.

The working element of a pinch valve – also known as a clamp valve – is an elastomeric tube or sleeve, which can be squeezed at its mid-section by a mechanical system until ultimately the tube walls are pinched or clamped together, producing full closure of the flow path. This flexible tube is either exposed (an open frame) or enclosed (a closed frame) in a body.

In its simplest form, a pinch valve can comprise a length of elastomeric tube, fitted with a pinch bar mechanism, incorporating a closure stop to prevent over-pinching of the tube. More commonly, the moulded rubber tube is housed in a metal body, which also incorporates the pinching mechanism. This can be a simple screw operated mechanism, where the pinch is applied only to one side of the tube, or a differential screw controlling two pinching mechanisms working in vertical opposition.

BMG’s open frame pinch valves, which have been developed on the successful design of BMG KLEP’s patented FPV diaphragm valves, are 100% locally manufactured and are available in many different materials, with various pressure ratings, to meet exact requirements.

This range is available from BMG with different linings – for example, soft rubber, hard rubber, Butyl rubber, Halar and jumbo rubber. The lining and diaphragm design increases the service life of the valve, due to high abrasion and chemical resistance properties of individual linings and diaphragms.

BMG’s full range of industrial slurry valves is highly efficient for the control and isolation of abrasive slurries in many industries, including power generation, chemical and petrochemical, cement handling, water treatment, mining, quarrying, pulp and paper.

BMG’s extensive range of components for fluid technology systems and general industrial applications comprises valves, hydraulic hoses and fittings, accumulators, cylinders, heat exchangers, pneumatics, hydraulic motors and hydraulic plumbing, as well as pumps and reservoir accessories.

Fluid technology services also cover project engineering and consulting, cylinder design and manufacture, training, repair and testing, as well as onsite container services.