16. Lube tip: identifying commercial oil brands

QUESTION: Why can’t my condition monitoring lab specify which brand of oil is in use?

ANSWER: Specific tracers can be found in many commercial products – they are included in order to help oil companies to make their own products identifiable. However, when conducting oil analysis, the properties that are routinely monitored by a condition monitoring company, the properties that are usually monitored are elementally generic, and often incorporate elements that are commonly included in many lubricants with the same classification and purpose.

An oil analysis laboratory can determine whether or not the same product is being used as your referenced oil, as well as whether it is typical of the type of oil (application) that is required. However, it can be virtually impossible to identify a specific brand name, due to many factors, including fluctuations between batches, similarities to other oils, and formulation changes.

17. Lube tip: aftermarket oil additives can backfire

Be careful when adding additives to oil – in some cases, when the amount of a particular additive is increased, it may enhance one property of the oil, and simultaneously cause another property to be less effective.

Oil quality can be affected in instances where the recommended concentrations of additives are no longer accurate. Some additives may be in competition with other additives for the same space on a metal surface. For example, the addition of a high concentration of an anti-wear agent may result in the corrosion inhibitor being restricted in its effectiveness in the oil. This may lead to a growing number of corrosion-related issues.

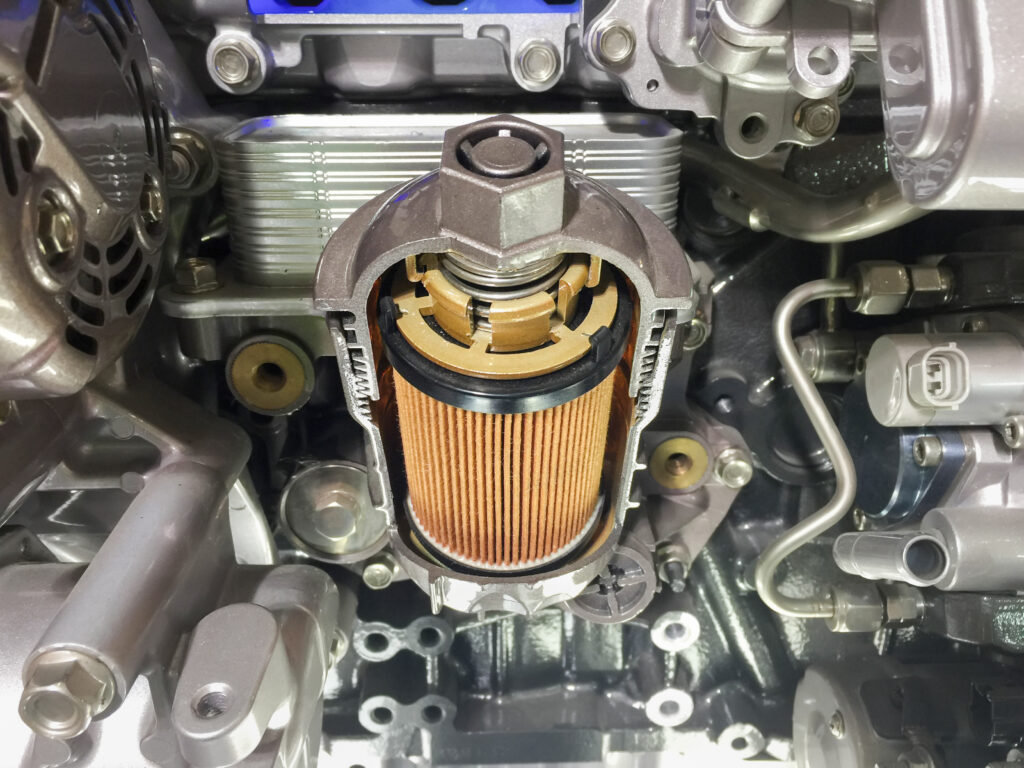

18. Lube tip: oil filtration systems – then and now

Oil filtration was not a feature in the earliest car engines. Purolator invented the oil filter in 1923, when Ernest Sweetland and George Greenhalgh patented the first automotive oil filtration system. They named their invention “Purolator”, short for “pure oil later”. Following this, full-pressure lubrication systems became available.

Fast forward many decades to the present day, when the modern full-flow filter is standard on all automotive engines.

Prior to this, filtration systems began to be incorporated into mass-produced vehicles in the 1940s, followed by a revolutionary change in the 1960s, when oil filter changes became more convenient as disposable filters (also known as ‘spin on’ filters) made their appearance.

From the 1970s and well into the following few decades, the efficiency of filters was overhauled. This was achieved by making changes to the internal construction of the filters.

In the 2020s, current automotive engines, regardless of whether they are petrol or diesel, are equipped with filtration that can improve the cleanliness of oil – a major factor in extending the life of the engines, and the oil. Visit www.wearcheck.co.za for more condition monitoring information.

19. Lube tip: hydraulic fluid maintenance

It is important to ensure that hydraulic fluids are kept cool. Importantly, the bulk oil temperature at the reservoir’s exterior should at no time exceed 60°C.

Essentially, hydraulic fluids should always be kept clean. Hydraulic experts agree that fluid contaminated with wear particles, dirt and other matter results in between 75% and 80% of hydraulic failures. Most high-pressure systems have very small clearances between wear surfaces, which means that contamination control is a critical part of maintenance and machine longevity.

Fluid leaks should be fixed immediately. If oil can find a way out, that means that dirt and other contaminants can find a way in. Furthermore, a worrying statistic is that a leak of one drop per second leads to 1,500 litres in a year – this can lead to an expensive loss, if left untreated.

20. Lube tip: synthetic oils vs. mineral oils

Query: “Relating to gearboxes on trucks, if the owner/ driver doesn’t know if the gear lubes are synthetic, is there a fool-proof way to determine this without having to send a sample to the lab? Some oil manufacturers colour their synthetic oils, while others don’t. What would happen if the oils were to be mixed or topped up with the wrong oil?”

WearCheck’s answer: The colour of the lube is simply a dye. There are no standards, and manufacturers can and do change colours whenever they please. Unfortunately, there is no reliable way of differentiating between mineral and synthetic in the field. However, because synthetic base oils are white (meaning transparent) as compared to mineral oils, which have a darker natural colour (due to aromatics, sulphur and other impurities), this may be a distinguishing factor. Note, however, that despite the fact that the base oil of a synthetic is white, the additives can add considerable colour (darkening) to the finished oil.

In the laboratory, you could distinguish synthetics from mineral oil by looking at a combination of physical properties including VI, flash point, pour point and aniline point. There may also be different elemental additive chemistry.

Generally, in the type of application you are talking about, the synthetic gear oil will likely be polyalphaolefin (PAO) based. PAOs are very similar chemically to mineral oils, so mixing the two should not cause a compatibility problem, especially if both oils are the same API classification.

However, if a synthetic is required, such as for cold-temperature operation, using a mineral by mistake may cause other problems.

Also, be aware that in industrial applications, some synthetic gear oils are polyglycol (PAG) base stocks, which are chemically incompatible with both PAO synthetics and mineral oils. In this case, mixing will result in serious incompatibility issues. Visit www.wearcheck.co.za for more condition monitoring information.