When cranes suffer from premature wheel wear, rail wear, structural component failures, crane noise, bad positioning or drive faults it is normally the result of incorrect crane geometry. Konecranes’ CraneQ Geometric Survey and RailQ 3D Runway Survey assist in finding the cause of these symptoms to so that major problems and costly downtime can be avoided. They work together to create a complete view of the crane and rail geometry to be inspected and assessed.

Ian Grobler, Sales Manager for Konecranes and Demag South Africa explains “The CraneQ Crane Geometric Survey and RailQ 3D Runway Survey are used to verify the alignment and square of a crane and to deliver accurate information on the alignment of the rail. Both surveys help locate where the problem lies when an operator experiences a performance that is problematic. The surveys provide recommendations for any needed corrective actions with a highly detailed and accurate analysis”.

CraneQ

Cranes that are straight, square, and aligned, experience less repair costs and have a higher level of reliability. The CraneQ Crane Geometric Survey provides the information that is required for detailing the alignment and the square of a crane. It measures dimensional tolerances of wheels, guide rollers, end trucks, girders, and other components of the crane.

The CraneQ Survey provides more accurate information than traditional surveying techniques because it is based on advanced surveying methods developed specifically for crane geometry. Konecranes’ specialised software and their skilled survey technicians will provide a geometric analysis of your crane as well as present feedback on what corrective actions need to be taken.

The survey also minimises downtime due to component wear by assuring correct component alignment.

RailQ 3D

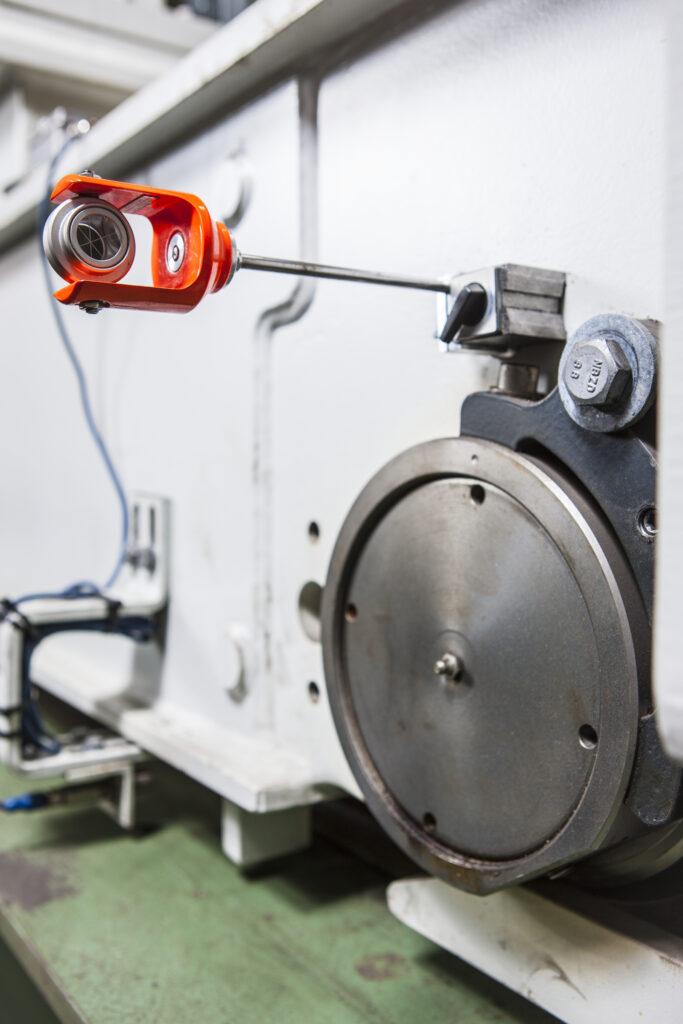

RailQ 3D Runway Survey uses high-definition surveying techniques combined with point cloud data analysis to provide information on runway condition. The 3D visual inspection will provide information on runway span, straightness, elevation and rail-to-rail elevation.

Symptoms that may indicate the need for a runway survey:

- Crane tracking and skewing issues

- Excessive wear on wheels and rails

- Loose rail fasteners

- Abnormal noises during bridge travel

- Frequently replacing bridge couplings, rail splices, rail sections and crane wheel axles

- Broken wheel flanges, etc.

Two major benefits resulting from the RailQ 3D Runway Survey, are that it is safer to perform than a traditional runway survey because it uses a remotely operated data collection instrument, and that the survey gathers more data in less time than a traditional survey delivering the same information.

“Performing RailQ 3D as part of a periodic inspection program on your critical production crane runways helps identify chronic issues. This approach allows you to plan maintenance far in advance and implement corrective actions during planned outages and production stoppages to limit the effects of lost production.” said Grobler.

“It’s not rocket science to see the benefits of the CraneQ and RailQ 3D assessment interventions. The cost savings that can result from the analysis of highly accurate data is immense, especially when preventive maintenance is scheduled. Couple that with decreased downtime in the production cycle makes it a win-win situation for all industries that require continuous cycles of production” concluded Grobler.

All CraneQ and RailQ 3D Survey reports are loaded onto the your Konecranes customer portal for quick and easy access by the customer.