Thyssenkrupp Uhde South Africa first opened its door to the local market in 1959 with engineering as the mainstay of its service portfolio. By the early 1970s, procurement, construction and management capabilities were added. The organisation continued to evolve, developing into a competent, diverse, and capable contractor that efficiently manages an extensive range of project types, technologies and customer requirements across the Southern African region.

The ability of the local subsidiary to tap into the specialisation available through its parent company, thyssenkrupp Uhde GmbH in Germany, while applying agility and local expertise to successfully deliver to very specific customer requirements uniquely positions the South African office in the market. “We work seamlessly with global technology providers (both thyssenkrupp and 3rd party) and we are competent and familiar with leveraging a global supply chain,” states Richard Kirk, Head of Project Management and Services at thyssenkrupp Uhde South Africa. “We apply our learning from diverse project contracting environments to our entire value chain of cutting edge technologies and EPC(M) solutions. This makes our local office efficient and effective.”

Thyssenkrupp Uhde’s engineering services include concept, Front End Engineering & Design (FEED) as well as basic and detailed engineering across all disciplines within a single integrated team. The competent local EPC(M) team of specialist individuals can work within a wide range of both thyssenkrupp Uhde and 3rd party technologies with global collaboration.

Tendering, bid evaluations, purchase orders, contract awards and management, logistics, quality control, technical compliance and expediting are some of the capabilities that fall within the company’s procurement scope. “Procurement/commercial contracts provide a full service in acquiring the technical requirements and delivering these within budget,” notes Kirk.

Thyssenkrupp Uhde’s extensive construction service portfolio comprises construction, contract, work package and customer interface management; quantity surveying; planning; material and cost control; modularisation; health, safety, security and environment (HSSE) compliance and management; quality control; testing and handover; deviation, concession management, etc. Kirk points out that stakeholder management is a vital and yet often overlooked component of successful construction management and here too thyssenkrupp Uhde has the necessary know-how.

The management portion of EPC(M) encompasses the full spectrum of project management, planning, material and cost control, modularisation, and HSSE. “Effective project initiation, monitoring and control, reporting, risk management, change management, and project close-out also form an integral part of our management solutions,” says Senior Piping Engineer at thyssenkrupp Uhde, Sundip Lokhande.

Thyssenkrupp Uhde’s EPC(M) capabilities can essentially enhance any project irrespective of the nature or technology involved. The organisation’s ability to offer the complete EPC(M) portfolio offers several advantages that, according to Kirk and Lokhande, deliver cost-effectiveness and efficiencies to customers.

Kirk explains, “By keeping the same team throughout the project means that there is no need to change the team between engineering and construction. Subsequently the same team is able to develop along with the project, avoiding the time and costs involved in having to develop a new team. From an efficiencies point of view, there is for example, no need to ‘on-board’ a procurement lead and team half way through the project especially if they have been engaged from the project get-go. This helps to avoid restraints and mitigations throughout the project, reducing the overall risks and ensuring timely delivery.” Lokhande also highlights the benefits of single point responsibility as well as savings due to fixed costs associated with the agreed schedule.

“Our EPC(M) services add value to all our technology offerings including scanning, green technologies (hydrogen, ammonia, methanol, etc.) as well as to our modularisation and refurbishment capabilities,” affirms Kirk.

“Having all these core competencies eliminates or greatly reduces the need for multiple partners, sub-contractors, etc., and allows for greater productivity in completing a project.” He adds that this approach also has the ‘soft’ benefit of maintaining consistency across projects and teams, leading to a better understanding of the technologies, translating into more insightful engineering, and subsequently more competent project completion.

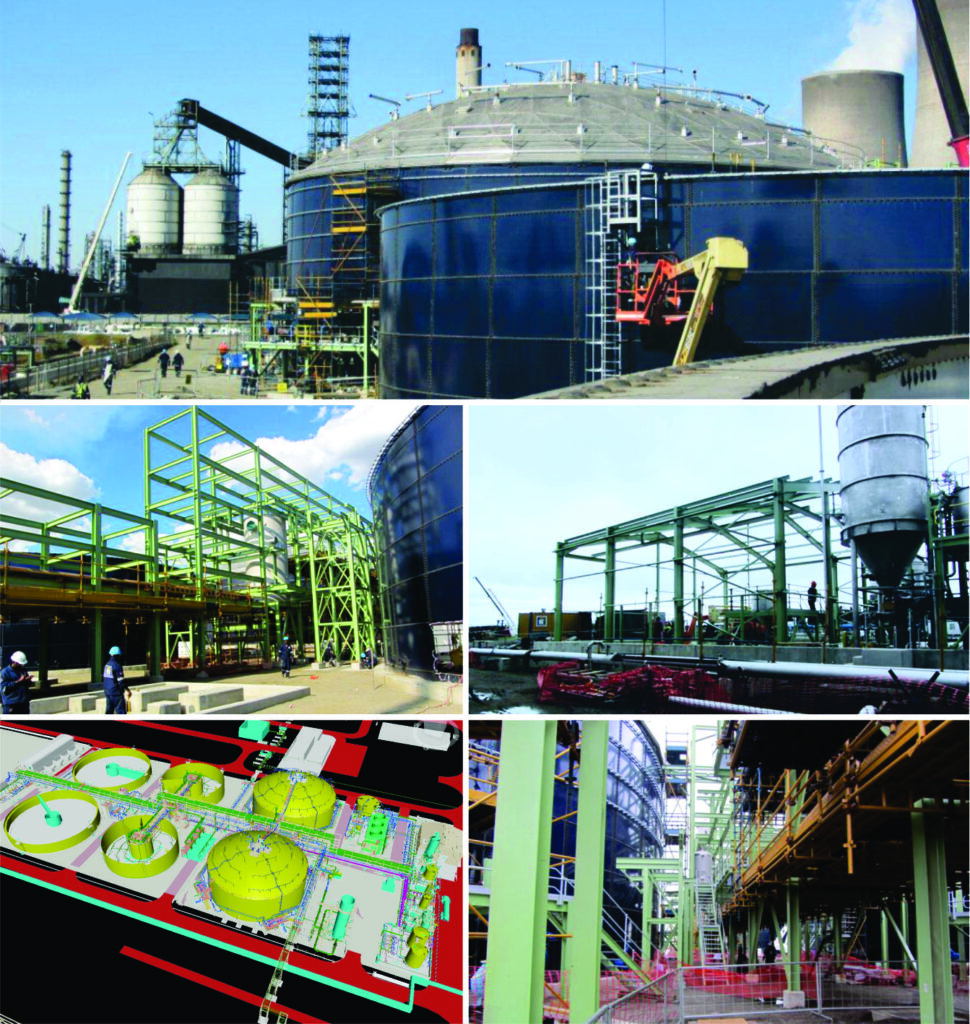

Recent EPC(M) projects successfully completed by thyssenkrupp Uhde South Africa during its 2021/2022 financial year include Liquid Sulphur Degassing, DU10, a Crude Flex solution in Saldanha bay (Western Cape) and an Ammonia Tank Refurbishment project in Richards Bay (KwaZulu-Natal). “A Seal Gas Upgrade for a leading refinery in the Free State is currently in progress,” affirms Kirk.

The combination of core competencies, specialised local expertise and agility, and access to global support, has positioned thyssenkrupp Uhde South African as a leader in the engineering and project contracting industry. Furthermore, the local office has been able to maintain a competitive edge in the market by providing a superior quality services chain.