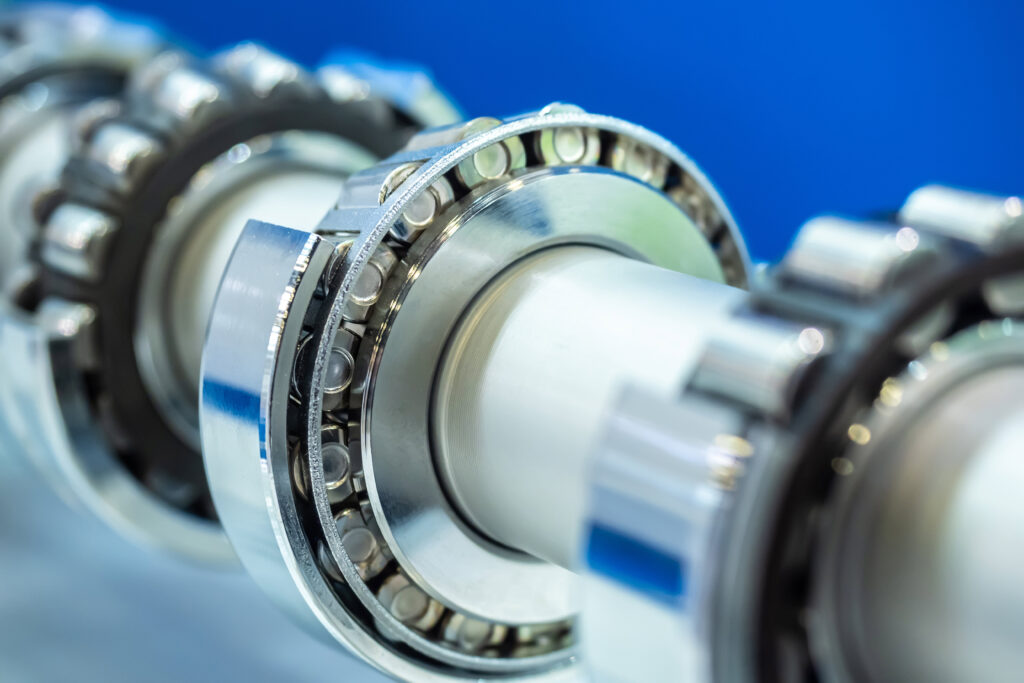

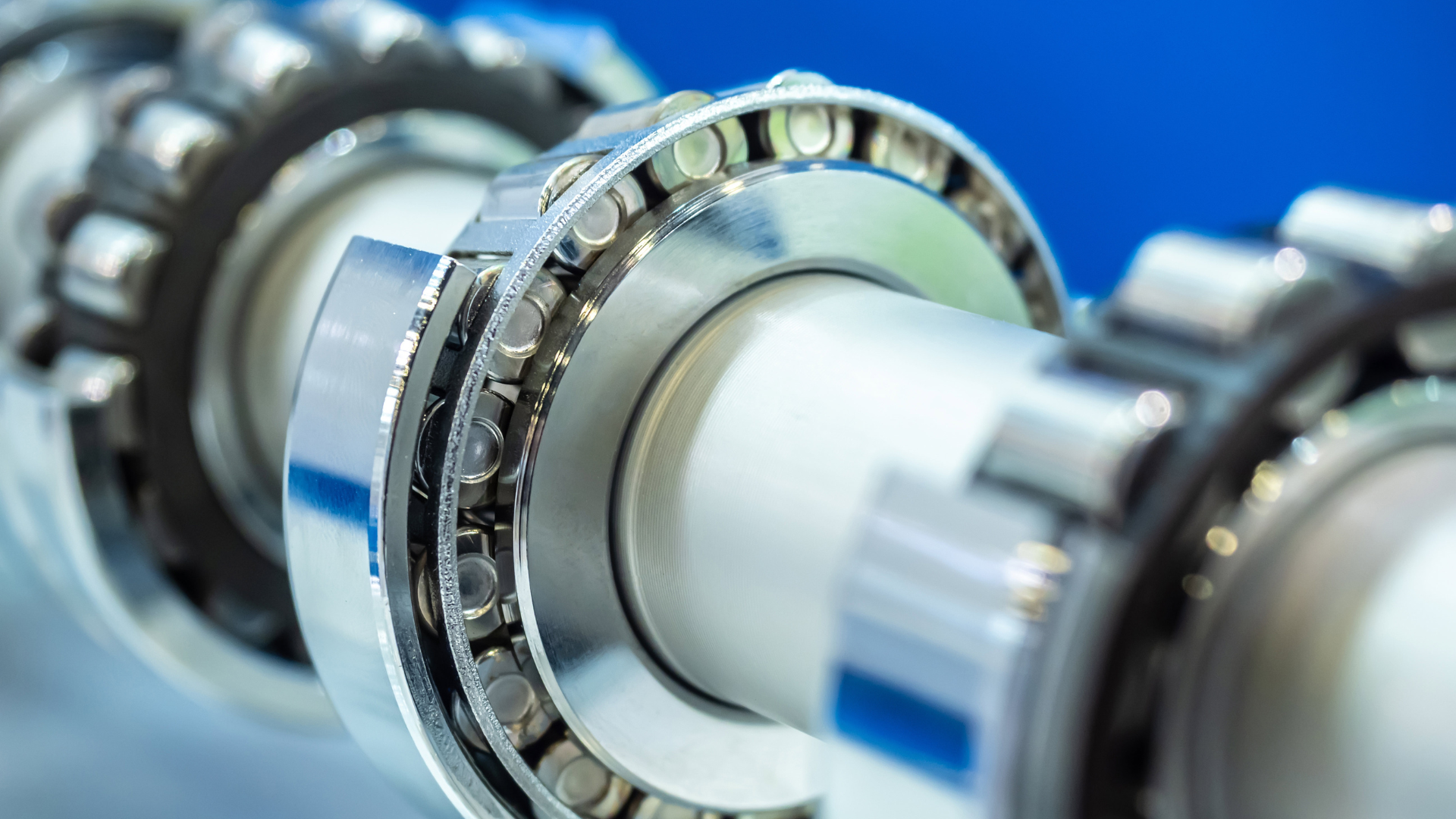

Plain bearings are often used in intensive applications because of their ability to operate for a long time under heavy loads and their low maintenance needs, even in harsh operating conditions. Despite this, their resilience doesn’t mean that they are immune to failure and some of the common causes of plain bearings failures include metal fatigue, misalignment, localised rapid wear and trapped dirt forming grooves in the bearing components.

However, there are ways to prevent even these ‘common’ failings from happening.

Colin Ford, MD of Lubrication Engineers (LE) South Africa explains that the correct lubrication is one of the most important ways to mitigate plain bearing failures. “Even though plain bearings don’t necessarily have complex lubrication requirements, the use of quality lubricants can prevent many of the common causes of bearing failures,” he says.

Poor lubrication, including insufficient lubrication or using the incorrect lubricant can appear in a plain bearing as rapid wear, often in one spot, until the surface completely breaks down. “An experienced lubrication consultant can help identify the correct lubrication solution for an application and plain bearing component to prevent this,” says Ford.

The right size for each application

The large bearing area on plain bearings means that they are able to carry heavy loads. However, Ford says that the right size bearing also needs to be selected for each application and that they should have the proper clearances, supported by good lubrication. “When these factors are in place, plain bearings can be better than antifriction bearings for carrying heavy loads or shock loads,” he adds.

To get the most out of plain bearings, bearing surfaces should be completely separated by a film of lubricant. Most plain bearings will rapidly get ruined if this film wears out. When the bearing is moving and correctly lubricated, friction decreases to almost the low point of antifriction bearings.

Misalignment is another cause of failure in plain bearings as it can cause disfigurement. Although it can sometimes be difficult to identify as the source of the fault, misalignment between a journal and shaft is usually easy to see. When studied closely, the wear pattern will reveal a skewed or unbalanced pattern. Sometimes a thrust load is also indicated. “This can be mitigated by using the correct lubrication to support any oscillation without it turning into long-term misalignment,” says Ford.

Foreign material and dirt can also cause bearing failure when particles create grooves in the softer bearing alloy. “The tracks are plainly visible either as large, long straight grooves, or as smaller particle tracks that wander. Lots of small, hard particles will cause multiple small, straight scratches, often resulting in excessive wear. If the foreign material is large or hard, it may become embedded. Lubrication is an excellent solution for preventing this problem because by nature it traps and removes dirt from the bearing system,” explains Ford.

LE includes proprietary Almasol and Monolec additives in its products that are particularly helpful in lubricating plain bearings because they significantly reduce operating temperatures in the bearings. This makes them effective in reducing wear during the critical start-up and shutdown periods of operation.